Chapter 1: Defining Value - A Lean Imperative

- Rod Morgan, LSSMBB, Head of Faculty, RPM-Academy

- Sep 27, 2018

- 5 min read

Updated: Sep 30, 2024

Chapter 1: Lean Principles, Defining Value and the Eight Wastes

I recently delivered, on a behalf of a client, a two-day “Introduction to Lean” session. In an effort to make sense of the client’s training content, I scratched out three flip charts to help summarize for the students what Lean is all about. 200+ slides now condensed into three flip charts. Overproducing, one of the eight wastes I’ll cover in a subsequent blog, applies equally to training materials.

“Lean is easy to understand but very hard to do”, is a phrase I often employ at the beginning of these introductory sessions. What I believe is important is that the concepts, tools, methods and even language of Lean be tailored to the audience (industry sector, type of services and products represented, etc.). “Adopt” and “Adapt”, and on rare occasions, “Abandon” decisions need to be made so the “clothes” offer a better “fit” when applying Lean.

This first in a series of blogs will examine each of the key elements of Lean, perhaps providing additional insight for those new to Lean, and a chance for more seasoned practitioners to also share their thoughts – all ideas and advice welcome.

Today we explore the important initial step for any Lean journey: “Defining value”.

DEFINING VALUE

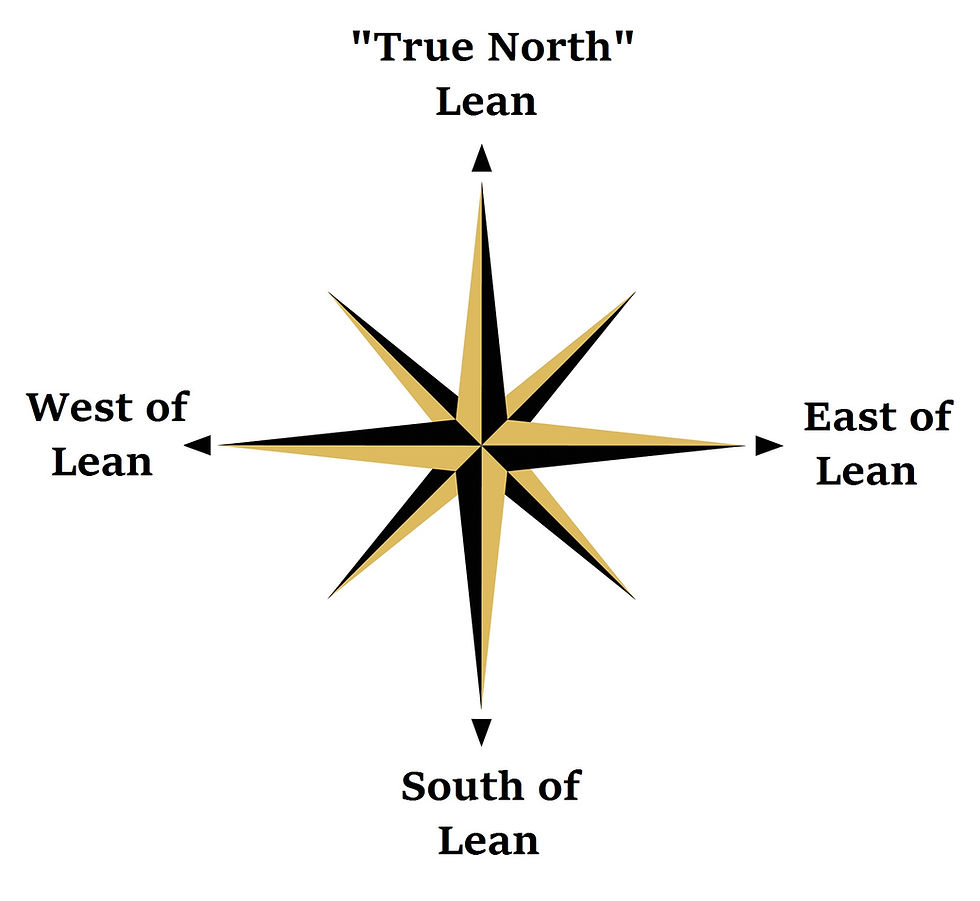

The first of five key Lean principles, a concise and unambiguous definition of value provides a shared compass in a Lean organization. A compass that all team members can use, from senior management to front-line staff, whether considering short and long-term strategy, day-to-day assessment of performance and operations, or focused continuous improvement (project) efforts.

Similar to crafting “mission, vision, and values” (MVV) statements, defining value is an incredibly important first step in any Lean journey. Although they should be aligned, the Lean definition of value should not simply be a replication of MVV. Lean is an enabler of goal achievement and strategy, not a strategy in and of itself.

The purpose of meticulously defining value is to create an overarching statement that can be employed by every person in an organization, and extended into the supply chain, providing a universal compass for assessing the work they are doing and the resources being consumed, including time.

“LEAN THINKING”

James P. Womack and Daniel T. Jones, in their seminal book, “Lean Thinking”, (ISBN 9780743249270), include the following definition of value;

Value is defined by the customer (externally focused) and is only meaningfully expressed in terms of a specific product that meets the customer’s needs at a specific price and specific time. A common error in traditional manufacturing operations is to define value internally (internally focused) and, if the customer fails to respond, the product is modified or the price is adjusted or a different marketing strategy is tried. Lean Thinking must ignore existing assets and technologies and rethink the business on a product-line basis with strong dedicated product teams. It must also redefine the role of the technical experts and re-evaluate where to create value for the customer.

While many organizations have adapted (and shortened) that definition over the decades, the intent remains unchanged… focus on value from the customer’s perspective. Here’s one example offered by a US government agency;

Value: A capability provided to a customer at the right time at an appropriate price, as defined in each case by the customer.

And another definition offered by Quality America Inc.;

Value-Added: An activity is value-added if a customer is willing to pay for; it changes form, fit or function of a product or service; it converts input to output; it is not waste.

If you search the internet, you will find many examples, each with its own “spin” on what value is.

Defining value… how hard can that be? Aren’t we already focused on the customer?

But… value can easily be confused and distorted within organizations and across their respective supply chains as the processes of designing, sourcing, producing and delivering products and services can be complex with many tasks, activities, and associated consumption of resources with no value added for the customer whatsoever.

These non-value adding activities are the focus for continuous improvement and improved design as organizations try to “lean out” their value streams – the chain of activities that a firm performs in order to deliver a valuable product or service for the market.

When engaging with clients that are considering the deployment of Lean, I ask them to think about their definition of value, explaining why this has to be their first step in what will be a never-ending journey… a way of conducting business and delivering products and services.

For those clients that have already “deployed” Lean, I typically find that they have NOT crafted that definition! How do they possibly expect their entire organization to navigate the waters of Lean, in the same direction, without that all-important compass?

As mentioned previously, I encourage, in fact, challenge organizations to craft that all-important definition of value, adapting it to best fit their environment, yet staying true to the intent advocated by Womack and Jones. Here are some examples for you to consider;

Manufacturing: Any process step, activity or task that transforms the deliverables of a process such that the customer is aware of it AND is willing to pay for it. Value is always stated in the eyes of the customer.

Healthcare: Any activity or task that moves the patient through awareness, education, prevention, diagnosis and treatment, is performed correctly the first time while meeting health, safety and regulatory standards, and the customer and/or community is willing to pay/fund that activity or task.

Public Sector/Government: Any process step, activity or task that transforms the deliverables of a process such that the customer and the community is aware of it and is willing to pay and/or fund it.

So, what’s your firm’s definition of value? What “compass” have you provided for your entire team to reference as they go about their work day, engage with clients and customers, and participate in continuous improvement projects? If you have trouble locating that definition, then that may be the sign of an even greater problem. For, it is only with this very definition that we can move forward successfully with our Lean journey.

Clayton Taylor, a Certified Six Sigma Master Black Belt working in the Office of the Executive Vice President, Treasurer and Chief Financial Officer at Arizona State University, offers an excellent narrative for their organization (https://service.asu.edu/blog/value-added-and-non-value-added-process-steps);

To provide any product or service, you have to use resources like money, materials, labor, time, and information. The goal is to provide the greatest amount of value to customers while utilizing the least amount of your resources. This idea of adding value to products and services is a key concept of Lean. It is defined as anything for which the customer would be willing to pay. If what you are providing is not something the customer would be willing to pay you for, then you are not providing value to the customer.

Any time you begin analyzing a process, you want to look at each step and determine if it is contributing to the value of the desired output. Each step can be classified into one of three categories:

Value-added

Non-value added, but necessary/required

Non-value added (waste)

And that… is just the beginning!

Chapter 2 in this blog series will explore the “Five Key Principles” of Lean… well, four since we have already addressed Principle 1, Define Value.

You can register for free to RPM-Academy Online and access four free courses, including our popular "Lean and Green" program. Go to: https://platinum-rpmacademy.talentlms.com

Be well. Be safe. And keep adding value!

Comments